Chapter 7 - The Wing

Section 4 - Wing Internals

Slosh Gates

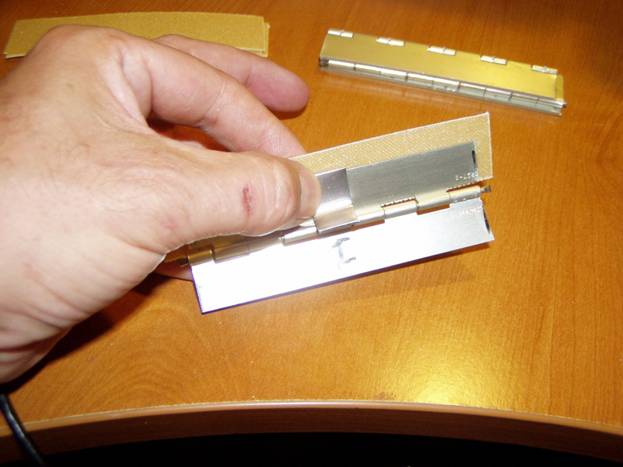

To make the bond on slosh gates, cut sections of the MS20257P piano hinge material 5 inches long. Permanently swage the hinge pin in place. Cut a small piece of aluminum sheet, .020 or so, ½” X 1” and bend it into a small angle to provide an upper stop. This will prevent the slosh gates from sticking open. Finally cut strips of pre-cured 2 layer fiberglass laminate the size of the hinge . These are then riveted together as a unit using flat head rivets. Countersink them into the procured laminate so we have a flat surface on the back to bond to.

Parts to make Slosh Gates

Slosh Gates

The slosh gates are bonded into place over the openings in the B and C ribs after all coats of fuel proofing resin have been applied to the internal fuel bays, but before any fuel proofer compunds such as polysulfied epoxy, have been applied. They are positioned so that the door swings free and there is about an 1/8" gap at the bottom in case they get stuck closed.

Slosh Gate Bonded in Place

Complete.