| |

|

Home

The Manual

Downloads

Contact

Disclaimer |

|

|

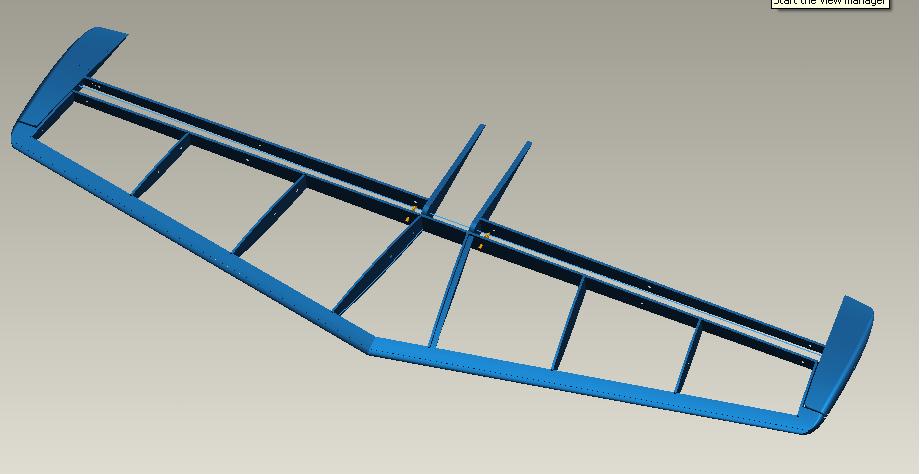

Installing Hinge Nutplates

Jig for Drilling Nut Plate Holes

Nut plates are used throughout

the tail construction to attach the hinges and the weldments

to the fiberglass structure. The photo above shows how

a simple fixture can be used to speed the drilling of accurate

holes in the nut plates.

Start with a

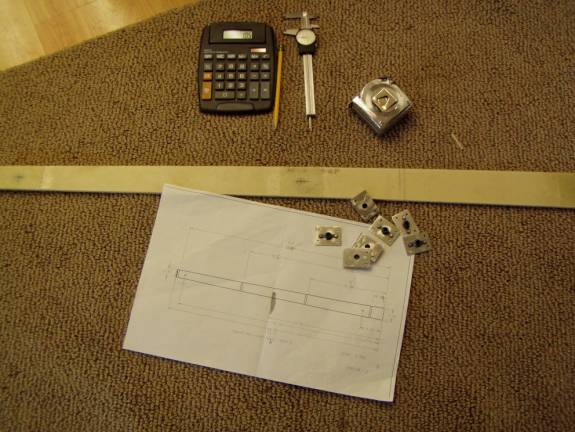

Nut Plate Parts

There are two sizes of nut plates used in the construction of the

horizontal and vertical stabilizers, one uses a K1000- 4 nut plate

and one uses a K1000-5 nut plate. Both of these are secured to the

aluminum plate with xxxxx rivets.

Completed Nut Plates

When installing the nut plates there are several important points

to keep in mind:

- The hole through the spar should be drilled over sized so the

bolt can move around allowing proper positioning of the hinge.

- Insure that you are putting the nut plate on the correct side

of the spar. One side had two extra layers of fiberglass

applied, this is the side for the nut plate. This should

also be the side you have marked the location of the horizontal

stab ribs, as seen above, since this will be the inside of the

stab.

- When installing the nut plates on the Horizontal stab spar it

is important to get the hinge bolt dead center of the spar. Use

a set of calipers to achieve this as seen below.

- When installing the nut plates on the Elevator Spar it is not

only important to get the hinge bolt dead center of the spar, but

also to insure the spacing is correct to match the spacing of the

horizontal spar hinges. This is actually easy to do, as you

will bolt the eyebolt side of the hinge to the rod end side and

use the horizontal spar as an adjustment fixture for the elevator

spar.

- Once you have mounted the nut plates for the elevator spar (this

is done later during the assembly of the elevator), you must mark

the left and right elevator spar sides as they will differ slightly.

<

Install Eybolt or Rod End to Secure Nut Plate

Here we are using the calipers to insure the eyebolt is exactly centered

on the spar.

Installing Nut Plates

To install a nut plate with pop rivets:

- first properly locate the hole as above. It is best if

the hole is slightly oversized.

- Thread the eyebolt into the nut plate, insuring one last time

you have it on the proper side of the spar.

- Drill a single #30 hole through the single layer of fiberglass

using a hole in the nut plate as a guide. Do not drill all the

way through the spar (if you do, not to worry). Install the

first pop rivet once you are happy with the alignment of the plate.

- Finally, drill the remaining three holes and install the final

pop rivets.

Installed Nut Plate

Looks Good.

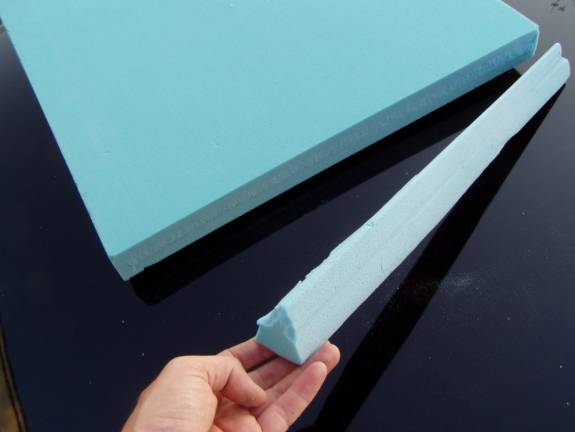

Fabricating Leading Edges

Leading Edge

Clamping Scheme for Long Straight Cuts

The leading edges are

cut from the 2 lb. Urethane foam. Here we shaped the leading edges before they were installed

on the horizontal stabilizer. In hindsight this was too much trouble

for no gain. Just cut oversized rectangular shaped pieces from

your block of foam.

Leading Edges Joined

Two strips of foam are needed for each side of the horizontal

stab leading edge. Epoxy the two strips of foam with micro

and then glass the aft side of the strips to form the leading edges.

Leading Edges Fiberglassed

A single layer of BID is applied to the aft face of the leading edge.

Completed Leading Edges

Two leading edges ready for assembly. Again just use rectangular

blocks instead of attempting to shape the leading edges before hand.

|

|

|

|

|

|